Each of my flags is made from 14 individual pieces of wood and I source all my lumber locally from trees grown here in the Pacific Northwest, mainly Douglas Fir and Pine of Poplar. I mill all the lumber down using my table saw, from a rough stock piece of 2×4 to the 1×2 pieces that I use for my flags.

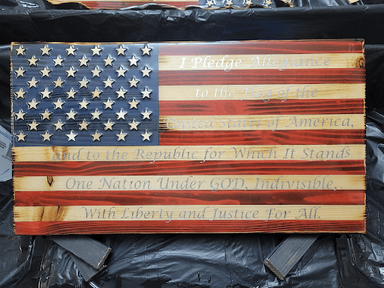

DIY projects with American flag design on wood

4th of July and Memorial Day Patriotic Crafts

USA Shaped Carved Wood Waving American Flag Check out this lightweight, easy carved wood USA shaped American Flag. We designed this project so that NO table saw, band saw, planer or Dremel grinder were needed. We started the project with 1×2 pine and glued them together horizontally. This gives the same overall dimensions as wood flags made from 2×4’s but eliminates most of the work and quite a bit of weight. We used wood glue, pipe clamps and an angle grinder. Listed below you will find a complete list of what is needed. Check out our other easy DIY projects each with its own how-to video tutorial.

If you are going to build our American Flag corn hole Bags game board, you may want to watch this short how-to video. Its shows a simple way to get nice crisp paint lines. Perfect for many DIY projects.

Looking for fun and patriotic DIY projects for Memorial Day or the 4th of July? Look no further than DIY Easy Crafts and Projects! Our website features a variety of easy-to-follow tutorials with step-by-step videos, including flag-themed crafts, decorations, and more. Whether you’re looking to create a festive centerpiece, outdoor decor, or a handmade gift, we have something for everyone. So come explore our site, and don’t forget to give us a thumbs up and subscribe to our YouTube channel if you enjoy our content!

This video shows how to make your own Patriotic themed knife from an old automotive leaf spring and some construction paper. Yes, I said construction paper. Check out this short video to find out how. The metal etching technique used on this video can be used on any metal working DIY craft project.

Easy DIY Stars and Strips themed Patriotic Door decoration. This easy wood working craft has a two tone wood stained stars and strips. The short how to video even shows how this no bleed wood stain was done. This decoration is perfect as a 4th of July or Memorial Day decoration.

Looking for an easy and patriotic DIY craft project? Look no further than this carved wood American flag birdfeeder! In this tutorial, we’ll show you how to make your own birdfeeder with just a few simple materials and tools. The finished product is not only functional for your feathered friends, but it’s also a beautiful and unique decoration for your home. Plus, with the American flag design, it’s a great way to show your love for the red, white, and blue. Follow along step-by-step and create your own carved wood American flag birdfeeder today

Looking for an easy and patriotic DIY craft project? Look no further than this carved wood American flag birdhouse! In this tutorial, we’ll show you how to make your own birdhouse with just a few simple materials and tools. The finished product is not only functional for your feathered friends, but it’s also a beautiful and unique decoration for your home. Plus, with the American flag design, it’s a great way to show your love for the red, white, and blue. Follow along step-by-step and create your own carved wood American flag birdhouse today!

Easy clean crisp lines with wood stain, painters tape or adhesive vinyl stencils. This would be a great way to craft a wood stained Patriotic corn hole board.

Making a Patriotic Heat Transfer Vinyl Hat with the OIIEE 5-in-1 Heat Press | DIY Craft Tutorial Join us in this exciting DIY craft tutorial as Dan Berg from DIYeasycrafts demonstrates the process of creating a stunning patriotic-themed waving American flag heat transfer vinyl hat using the OIIEE 5-in-1 heat press. The design for this project was sourced from my daughter’s Etsy store, ABKR Creations. Watch closely as we guide you through the steps of importing the image into the Silhouette Cameo software, resizing it, and flipping it to create a mirror image for cutting. Remember to place the heat transfer vinyl with the shiny side down on the cutting mat and adjust the knife depth of the Cameo vinyl cutting machine to ensure it cuts through the vinyl but not through the clear trans film. Witness the precision as we weed the vinyl, removing the excess material, and then witness the magic as we use the heat press to apply both colors, resulting in this beautiful patriotic-themed hat. Get ready to showcase your love for your country with this custom-made accessory. Don’t forget to visit www.DIYeasycrafts for more inspiring craft projects and tutorials. Let’s get crafting!

With just a standard home iron, you’ll be amazed at how quickly you can create a unique and eye-catching design. We used a Patriotic red, white, and blue design from AB&KR Creations on Etsy (abkr.store). It was a breeze to download and import into our Silhouette Cameo software, allowing us to effortlessly cut the design out on heat transfer vinyl. To get started, we set up a towel on a solid countertop and adjusted our home iron to the cotton setting without steam or water. We covered the design with parchment paper and applied gentle pressure, heating each section of the transfer vinyl for 15 seconds. Then, we carefully peeled off the transfer film and covered it again with parchment paper, heating it for an additional 20-30 seconds. The end result was truly impressive, and we’re confident that our daughter will adore wearing her new “America: Land of the Free because of the brave” shirt.

Materials and Tools

And what materials and tools do you need for this project?

- 6 1x2x36″ boards

- 7 1x2x21 1/4″ boards

- 1 1″x12″ piece of Pine

- Glue

- Blue stain

- Red stain

- At least 2 brushes

- Hand sander (orbital or palm or block)

- Sand paper in various grits (60-80-150-220)

- Hand torch

- 1 1/4″ nails or screws

- Measuring Tape

- Chop Saw

- Table Saw

- Hammer

- Circular Saw

- Straight Edge

- Cordless Drill

- Carpenters Square

- Pencil

- Branding iron

Gearheart branding irons for wood are a great solution and perfect to give your projects that special touch. Check out these ideas for your branding iron.

For the Union section, you will need:

- Either a pre-bought custom Milled Union or a Stencil Kit

- White paint

- White vinyl

- Dremel rotary tool

- Or 1 1/4″ Wooden Stars

How Do You Make a Wooden American Flag?

I’d say there are 7 steps to making a wooden American flag:

Step 1: Cutting the boards

My lumber begins its journey at the chop saw and I begin by cutting the boards down to size. I need some at 38 inches and some at 24 inches. Following this, I set up my table saw to get my boards to the desired ¾ inch thickness.

Tip: If you don’t own a chop saw or a table saw, use a circular saw and straight edge.

This step can be quite time consuming but I always want to get the right consistency of dimensions for each of the boards I use. You could cut this step out and buy factory made 1x2s from a home improvement store.

The final board to cut is the board for the union section. I like to use pine for my union sections and I get a 1×12. I’ll use my chop saw to cut the board to a dimension of exactly 14 ¾ inches long and then use the table saw to cut it down to 10 ½ inches wide.

Step 2: Sanding

Once I have all my boards cut to size, I sand each of them down. This gets rid of any tool marks from the table saw and provides a nice smooth finish.

I use a corded random orbital sander with 60 grit sandpaper to start, then once I have sanded each board pretty well I move to 150 grit before wiping them down with a damp cloth to remove any dust and reveal the grain a little better.

After I have sanded and wiped down each of the boards I like to sort through them and pick out those with the best-looking grain patterns and those which are most similar. I need 7 boards with a similar grain pattern (4 at 24” and 3 at 38”) to use for my red stripes, and for the white stripes I look out for boards with really smooth, straight grains (3 at 24” and 3 at 38”).

When the boards are dry (10-15 minutes later) I give an extra sand to the 6 boards I will use for the white stripes using 220 grit sandpaper. This really smooths them out and makes them look sharp next to the red stripes.

Step 3: Staining

Speaking of the red stripes, we need to stain these boards. I use a water-based tintable stain that has been colored red. Before I stain my 7 boards I like to give them a good burn, not to char them but to really bring the grains out. Once this is done I put on my nitrile gloves and give them a coat of stain. When staining, don’t forget to also stain the top and bottom edges as well.

It’s important to use good brushes when staining your boards, as the better the quality of the brush, the smoother the coat of stain lays down. Once I have coated the 7 boards with stain, it’s a good idea to give the white stripe boards another wipe down.

The union section also needs to be stained, except this time with a blue stain. I take my torch to give the board a good burn, as I did with the stripes, and then use a tintable water-based stain coloredPatriot Blue.

Tip: Once stained, boards can take just an hour or two to dry. However, I like to leave them overnight so that the color really soaks into the lumber.

Step 4: Assembling

Now it’s time to get the clamps and the glue. I use a lot of clamps. 7 to be exact. And I glue my flags up in 3 stages: The top 7 boards, then the bottom 6 boards, and then finally all 7 boards glued together with the union section.

I glue my 7 short boards together using 3 clamps, starting with a red and ending with a red. Then the bottom 6 board, using 4 clamps, starting with a white and ending with a red. I set each section aside and let them sit for 24 hours. Now it’s time to get our stars on our union!

Step 5: The Union Section

I own a decent-sized CNC machine with a Dewalt router as its cutting head. I lay a union down on the table, line it up making sure it’s square, then fire up my machine and let it do its job.

If you don’t own a CNC machine, you have some options…

- Get a stencil kit and some white paint

- Get a stencil kit and use a dremel rotary tool

- Either make some or buy some wooden stars

- Buy some custom-milled unions from someone like me!

I’ve used all of these options since I started making flags. I originally started with a stencil kit and white spray paint, then moved onto using a dremel, then wooden stars, and finally ended up purchasing and building my CNC machine.

Step 6: Final assembly

After cutting, sanding, staining, painting and clamping your boards – it’s time for the final assembly.

I unclamp my sections of the flag and use a carpenter’s square and a circular saw to ensure I get a totally flush edge at one end of each section. I’ll start with the 24” section, line it up square along the bottom edge, and close to the short edge, and cut the section with the circular saw. I then simply repeat this process for one edge of the bottom section.

Next, I’ll get out a long set of clamps and glue the union to the freshly squared up edge of the top section of the flag. I’ll then use a different set of clamps to glue the bottom section to the top using a straightedge to make sure the newly squared edge of the bottom section is flush with the edge of the union.

Once all lined up, tighten all the clamps and wipe off any excess glue with a damp cloth.

Tip: If your union doesn’t sit flush with the top edge of the adjoining section, measure it and run it through your table saw to cut it so it is even and flush.

At this point, you just need to let everything dry.

Once it’s dry, take it out of all the clamps and lay it on its face. Now, you want to measure from your flush union edge. Measure 37 inches and place a mark. Repeat this down towards the bottom, line up a straight edge and use the circular saw to cut the entire length of the flag making it all flush.

Now measure in about 9 inches from each edge, both top and bottom, and glue and nail a 1×2 cut to approx. 19 inches as a support brace. Flip it back over, wipe it all down, and give it a finish with either a clear coat spray, or some polyurethane.

Finally, attach a hanging wire with a couple of D-rings and you’re almost ready to hang your flag somewhere proudly.

Step 7: Branding

There’s one final step to make your flag that extra bit unique and stand out above the rest in terms of quality.

I always use a handheld router with a 1/4″ round over bit and run it along all 4 edges. I then take my torch and lightly burn each edge, before applying a couple of coats of polyurethane. If the customer ordered it, I also epoxy coat it and after the epoxy is dry, I sand off the little epoxy nipples on the back and give a final sanding.

As the final touch, I brand my logo onto the flag using a branding iron from Gearheart Industry and then use a spray clear coat for the back to seal it.

One last question, why do you specialize in creating custom American flags?

It’s what I do! I’ve always loved working with wood and for me to own my own business, doing something that I really enjoy is just awesome! I’m so thankful to each and every one of my customers.

Showing support for our first responders and veterans is one of the reasons I started out down this path and I’ve enjoyed each step of the journey so far. And it’s no way near over.

I now sell DIY kits (which include precut stained lumber, the union and a hanging kit) if you also want to show support or if you just fancy having a go at making an American flag for the first time too!

Do you also want to sign your wooden American flag with a custom-made branding iron? Gearheart create branding irons for wood to order, so no matter what your requirements are, we will make something perfect for you!

- Share on Facebook

- Share by email

- Print this page

- Share on Twitter

- Share on Pinterest

Are You Ready to Leave Your Mark?

When you are ready to permanently mark a logo, monogram, name, or custom artwork onto leather, wood or other materials, Gearheart is ready to provide you with the best custom branding irons that money can buy. Check out our full range of products to find your next custom branding iron, or check out our gallery for some ideas!

Join Our Family of Wood Workers, Leather Artisans, and Many More.

From custom branded wedding favors to fine furniture creations, our clients’ creativity never ceases to amaze us.

Would you like access to exclusive content to get fresh branding ideas? Join our newsletter list.

Keep up to date with the latest news & updates