For those who are new to paint making, it may be better to test your paint on a piece of base material before starting your work.

WO2007009161A1 – Paint composition – Google Patents

Publication number WO2007009161A1 WO2007009161A1 PCT/AU2006/000989 AU2006000989W WO2007009161A1 WO 2007009161 A1 WO2007009161 A1 WO 2007009161A1 AU 2006000989 W AU2006000989 W AU 2006000989W WO 2007009161 A1 WO2007009161 A1 WO 2007009161A1 Authority WO WIPO (PCT) Prior art keywords water alkali soluble polymer paint composition composition Prior art date 2005-07-15 Application number PCT/AU2006/000989 Other languages French ( fr ) Inventor James Campbell Cobb Original Assignee Chroma Australia Pty Limited Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.) 2005-07-15 Filing date 2006-07-14 Publication date 2007-01-25 2005-07-15 Priority claimed from AU2005903740A external-priority patent/AU2005903740A0/en 2006-07-14 Application filed by Chroma Australia Pty Limited filed Critical Chroma Australia Pty Limited 2006-07-14 Priority to AU2006272435A priority Critical patent/AU2006272435B2/en 2006-07-14 Priority to EP06760851.3A priority patent/EP1904590B1/en 2006-07-14 Priority to CA2615196A priority patent/CA2615196C/en 2006-07-14 Priority to US11/995,516 priority patent/US7851545B2/en 2007-01-25 Publication of WO2007009161A1 publication Critical patent/WO2007009161A1/en

-

- C — CHEMISTRY; METALLURGY

- C09 — DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D — COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D5/00 — Coating compositions, e.g. paints, varnishes or lacquers, characterised by their physical nature or the effects produced; Filling pastes

- C09D5/06 — Artists’ paints

- C — CHEMISTRY; METALLURGY

- C09 — DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D — COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D133/00 — Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides, or nitriles thereof; Coating compositions based on derivatives of such polymers

- C09D133/04 — Homopolymers or copolymers of esters

Abstract

There is described a water-based paint composition comprising least one pigment; at least one alkali soluble polymer in an amount effective to increase the open time of the composition; at least one substituted amine in an amount effective to adjust the pH to about 7 to about 11: a binding effective amount of at least one water dispersible acrylic polymer; and an effective amount of at least one alkali soluble or alkali swellable thickener. A method of extending the open time of a water-based acrylic paint composition and a method of controlling the open time of a water-based acrylic paint composition are also described.

Faint Composition

Field of the InventionThis invention relates to water based artists’ paints and more particularly to improved water based artists 1 paint compositions.

ContentsBackground to the Invention

Acrylic paints dry as water leaves the paint. As water evaporates or is absorbed by the substrate to which the paint is applied, acrylic polymer particles coalesce into a continuous adhesive film. Within a relatively short period of time, approximately 10 to 15 minutes, a skin forms over the outer surface of the paint firm. At this stage the paint film is said to be “dry to the touch”. The thicker films continue to dry over time, the length of time varying with the thickness of the film. For very thin, films this may be a few minutes, while films half a centimetre in thickness or more may take weeks or months.

Once the skin has formed over the paint film, the film can no longer be worked. The artist is not able to change and adapt what is talcing place on the canvas using traditional techniques. Although the touch dry film could be painted over, the “wet in. wet” painting techniques are severely curtailed. The term “wet in wet” is used by persons skilled in the art to refer to painting techniques by which the artist creatively works and develops the wet paint on the substrate, adding, blending and altering the appearance over time to achieve the desired artistic result.

Temperature, humidity and air flow are environmental factors that influence the drying times of acrylic paint compositions. The time taken for a paint film to skin over can be extended somewhat by reducing air-flow, lowering temperature and increasing humidity. Manipulating such environmental factors may not always be possible or practical. Low temperatures (below about 9°C) may interfere with coalescence of the polymer particles resulting in paint film cracking, becoming powdery or failing to adhere to the substrate. Optimum humidity may be difficult to determine and maintain. ■ The nature of the substrate also influences the drying time of acrylic paint compositions. An absorbent substrate will draw moisture out of the paint composition and speed drying time. Sealing the substrate to reduce absorbency or selecting a nonabsorbent substrate such as metal or masonite will reduce the moisture lost through the substrate. Using a moist substrate can also reduce moisture lost through the substrate and increase humidity in the environment of the paint. ■ By soaking the back of a canvas with water or attaching wet rags or sponges to the back of a canvas, for example, the rate of drying of the paint film can be reduced. This technique has limitations and the water may also wash imparities out of the canvas into the paint film causing discoloration.

Humectants, such as glycerin or propylene glycol may be used as paint additives to extend the time taken for a paint film to skin over. As paint additives however, humectants tend to linger in the paint film. They can remain tacky and adversely affect outer coat adhesion. Most importantly they do not prevent fast drying of thin films of paint.

Disclosure of the Invention

The invention relates to a water-based paint containing at least one water dispersible acrylic polymer, the improvement comprising including in the composition at least one alkali soluble polymer in an amount effective to increase the open time of the composition and at least one substituted amine in an amount effective to adjust the pH to about 7 to about 11.

In one aspect the present invention provides a water-based paint composition comprising: at least one pigment in an effective amount to provide the desired pigmentation; at least one alkali soluble polymer in an amount effective to increase the open time of the composition, said polymer being selected from the group consisting of polymers soluble at ambient temperature and pressure in an aqueous solution having a pH of from about 7 to about 11; at least one substituted amine in an amount effective to adjust the pH to about 7 to about 11, said amine selected from the group consisting of Ci_6 alcohol amines, Ci_6 alkyl Ci-« alcohol amines and mixtures thereof; a binding effective amount of at least one water dispersible acrylic polymer; and an effective amount of at least one alkali soluble or alkali swellable thickener.

The composition also optionally includes one or more conventional additives such as dispersants, rheology modifiers, defoamers, coalescents and preservatives.

The term “open time” as used herein means the time during which the paint composition remains workable such that it may be blended and altered. The present inventor has surprisingly found that the period during which a water-based acrylic paint composition remains workable, i.e. the open time of the paint, can be significantly extended to free the artist to develop the artistic work over many hours. Rather than developing a paint skin in the normal way, within about 10 minutes, the composition sets gradually over time. Wet paint may therefore be applied over paint already on a substrate and may be blended with it and into it, giving artists time to create complex paintings while working at their own pace and with ample opportunity to revise and alter their work before it becomes fixed. The open time can be extended for several hours and for as long as a day by “using the composition of the invention and by periodically applying water to the paint film for example by sprinkling or spraying. The conventional acrylic binder, namely a water dispersible polymer, is prevented from forming a skin as the water evaporates. Whilst not wishing to be bound by theory, it is believed that the alkali soluble polymer forms a coating around the dispersion polymer particles preventing coalescence of those particles. A water resistant film is formed only when the amine evaporates and the alkali soluble polymers themselves become water resistant. Accordingly, the present invention also provides a method of extending the open time of a water-based acrylic paint composition comprising including in the composition at least one alkali soluble polymer in an amount of effective to increase the open time of the composition said polymer being selected from the group consisting of polymers soluble at ambient temperature and pressure in an aqueous solution having a pH of from about 7 to about 11; and at least one substituted amine in an amount effective to adjust the pH to about 7 to about 11 and optionally, periodically applying water to the composition. ‘

Alkali Soluble Polymer As used herein, the term “alkali soluble polymer” means a polymer which is capable of being solubilized at ambient temperature and pressure in an aqueous solution where the pH is alkaline. The solubilization pH of the alkali-soluble polymer is generally in the order of from about 7 to about 11. Preferably the solubilisation pH is in the order of from about 7.5 to about 10, more preferably about 7.5 to about 9.5. An alkali soluble polymer has at least one acidic or anion producing group. Examples of anion producing groups include but are not limited to carbpxylic hydroxyl, phenolic hydroxyl, active imido and sulfonamide.

The alkali soluble polymer is made to serve as an auxiliary binder and is not a conventional ingredient in acrylic paints. The proportion of alkali soluble polymer can be varied to manipulate the drying time of the paint composition. The higher the ratio of alkali soluble polymer to water dispersible acrylic polymer, the longer the drying time as long as a slow-evaporating amine is also present (as discussed below).

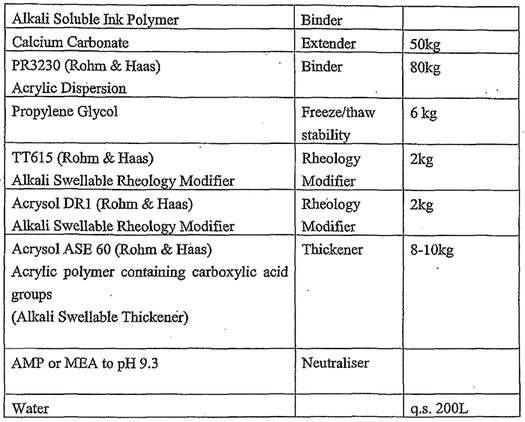

For a paint composition with a feel similar to a conventional acrylic artists’ paint the ratio of alkali soluble polymer to water dispersible acrylic polymer may range from about 1:4 to 1:20, preferably from about 1:5 to 1:10. In a 200L batch of paint for example where 80kg/200L of water dispersible acrylic binder is used and about 10kg/200L of alkali soluble or alkali swellable thickener, the amount of alkali soluble polymer may be in the range of about 4-20 kg/200L3 preferably 8-15 kg/200L, more preferably 8-12 kg/200L and most preferably 8-10kg/200L. This equates to ratios of alkali soluble polymer to water dispersible acrylic polymer of from about 1:4 to 1:20, preferably from about 1:5.33 to 1:10, more preferably from about 1:6.66 to 1:10 and most preferably from about 1:8 to 1:10.

For a paint composition with a feel more like a traditional gouache a ratio of alkali soluble polymer to water dispersible acrylic polymer may range from aboμt 1:1 to 1:3, preferably about about 3:4. This ratio gives a tough paint film which is less brittle and more fiexibile than a conventional guache but can still be applied thickly if desired.

Artists may wish to use paints in several different ways or techniques in the same painting and the paint is usually applied in successive layers. An artist may sometimes want a layer of paint to dry quickly, but more often wants to extend the open time, and being able to control what is happening is desirable.

A paint as described above with 80kg water dispersible acrylic binder per 200L and 8- 12kg of alkali soluble binder does not form a skin and can be kept “open” by spraying with a water atomiser from time to time as water evaporates and the paint becomes tacky. Mediums can also be used to give the artists even more control.

For faster drying, a medium made from water dispersible acrylic polymer applied to a paint film will swing the balance towards fast film formation, while for a slower drying paint, a medium made from alkali soluble polymer/ substituted amine swings the balance in the opposite direction. In a preferred embodiment therefore, the invention provides a method of controlling the open time of a water-based acrylic paint composition, the method comprising including in the composition at least one alkali soluble polymer in an amount effective to increase the open time of the composition and at least one substituted amine in an amount effective to adjust the pH to about 7-11 and periodically applying to the composition one or more of:

(a) water;

(b) a medium comprising at least one alkali soluble polymer and at least one substituted amine in an amount effective to adjust the pH to about 7-11 ; and

(c) a medium comprising at least one water dispersible acrylic polymer. Suitable commercially available alkali soluble polymers are flexographic ink polymers such as those manufactured by Rohm & Haas under the names Lucidene ™ .361 and Lucidene ™ 602 LS1 and Acrysol 1-62. Also suitable are Glascol™ LS 16, and the LE 500 series – LE 510, LE 520 and LE 530 manufactured by Ciba Specialty Chemicals and Joncryl 142 ™ manufactured by Johnson Wax Co.

Substituted Amine

Substituted amines are included in amounts sufficient to neutralise the■ composition to a pH in the range of about 7 to. about 11. Preferably the pH is in the range of from about 7.5 to 10, more preferably about 7.5 to 9.5. Suitable amines include

alcohol amines – and Cj-6 alkyl Ci-6 alcohol amines such as aminomethylpropajαol (AMP), monoeώanolamine (MEA)5 diethanolamine (DEA) and triethanolamine (TEA) and mixtures thereof. AMP and TEA and mixtures thereof are preferred. Substituted amines are selected so as to slow the evaporation of the amines thereby extending the time in. which the binders and thickeners (those which are water soluble or swellable under alkali conditions) may remain in solution.

Dispersiblc Acrylic Polymer

The present invention includes at least one water dispersible acrylic polymer. These polymers are conventional binders for acrylic paints, well known to those skilled in the art. Suitable polymers include water dispersible polymers containing one or more monomers selected from styrene, acrylates, alkylarylates and dienes. Polymers including acrylate, methacrylate and methyl methacrylate monomers are common.

The selection of water dipersible acrylic binder and the quantity to be used for the composition of the present invention is within- the skill of the person skilled in the art using routine trial and experimentation. Examples of suitable commercially available water dispersible acrylic polymers are PR 3230, ac 2235, ACI-1955 and Primal SF-017 manufactured by Rohm & Haas. Also suitable is Acronal 290D manufactured by BASF.

The water dispersible acrylic polymer is present in the composition of the invention in. a binding effective amount A “binding effective amount” of at least one ■ water dispersible acrylic polymer will be understood to mean that the at least one water dispersible polymer is present in an amount so that in combination with the at least one alkali polymer discussed above, it will bind the pigment particles together into a cohesive paint film upon drying. Thickener

One or more alkali soluble or alkali swellable thickeners are included in the composition of the present invention. Such thickeners typically comprise the aqueous emulsion reaction product of an unsaturated carboxylic acid monomer, e.g., methacrylic acid; a moήoethylenically unsaturated monomer different from the carboxylic acid monomer, e.g. ethyl acrylate; a macromonomer comprising a hydrophobic portion and an alkoxylated portion which is polymerizable with the other monomers; and a monomer having latent crosslinking functionality. Suitable thickeners include UCAR 146 and UCAR Polyphobe TRl 15, manufactured by Union Carbide and Acrysol DR-I, Acrysol DR-73, Acrysol ASE 60 manufactured by Rohm &

Haas.

The thickeners may be varied depending on the main pigments being used in order to get a uniform viscosity. The selection of alkali soluble or alkali swellable thickener and the quantity to be used for the composition of the present invention is within the skill of the person skilled in the art using routine trial and experimentation.

Pigment

One or more pigments may be included in the composition. Pigmentation provides colour and opacity and may contribute to other properties of the paint composition. A person skilled in the art will be aware that pigment particle size and shape, ease of wettability or properties relating to specific density contribute to the viscosity and application characteristics of the wet paint composition and ultimately properties of the dried paint coatings. A person skilled, in the art will therefore appreciate that the choice of pigment will have an effect on the choice of other ingredients such as thickeners.

It is well within the skill of the addressee to determine the appropriate selection of pigment and the quantity to be used using routine trial and experimentation.

Colour pigments may be organic or inorganic compounds, natural or synthetic and these may be used separately or in combination. Titanium dioxide is a common white pigment with a high refiractive index and excellent hiding power (the ability to render a paint opaque). It is frequently used with both coloured organic and inorganic pigments. Iron oxides range in colour from yellow and red to brown and black. Azo pigments are a common class of organic colour pigments. Pigments called “extender” pigments may be used in conjunction with other pigments. The use of extender pigments reduces shrinkage stresses within the paint film and increases the pigment volume content at relatively low cost. Extender pigments include those based on carbonates, silicates, sulfates, barytes and mica. The use of extender pigments aids in viscosity and flow control and reinforces the dry film strength.

Dispersant The composition of the present invention may include one or more dispersants.

These are conventional ingredients used to enhance pigment loading and dispersion stability. The dispersant may be nonionic or anionic surfactants. Anionic surfactants are preferred. Examples of suitable anionic emulsϋϊers include sodium lauryl sulfate, sodium dodecyl benzene sulfonate, dioctylsulfosuccinate, sodium polyoxyethylene lauryl ether sulfate, sodium dodecyl diphenyloxide disulfonate and other diphenylsulfonate derivatives, and sodium salt of tert-octylphenoxyethoxypoly(39) ethoxyethyl sulfate.

Suitable anionic surfactants are manufactured by Rohm & Haas under the trade marks Orotan 1124, Orotan 1288, Orotan 731 DP and Orotan 850. The skilled addressee is able to determine the appropriate selection of dispersants and the quantity to be used using routine trial and experimentation.

Other Additives

The composition also optionally includes one or more conventional additives such as rheology modifiers, defoamers, coalescents and preservatives.

Best Modes for Performing the Invention

The invention will now be further discussed with reference to the following examples. It is to be understood that these examples are illustrative and not restrictive.

Example 1.

Example 2

Ingredient Function Quantity (kg)

Peritione Orange Pigment 10kg Remainder as for Example 1 except no Quinacridone Magenta pigment

Example 4

4. Blue Black Pthalo Blue 10kg

Carbon Black 2.5kg

Remainder as per Example 1 except no Quinacridone Magenta pigment Exam le 5

The thickeners may be varied depending on the main pigments being used in order to get a uniform viscosity. The alkali swellable thickener in the examples may be substituted with other conventional alkali swellable thickeners as discussed above. The amount of Alkali Soluble Ink polymer may be varied to control the rate of drying. For Acrysol 1-62 in the examples above amounts may be varied from about 4kg to about 20kg/200L, Preferred amounts are from 8-15 kg/200L more preferably 8- 12 kg/200L. Less than 4kg does not achieve the desired effect.

The paint making process is the same for any colour and is the conventional procedure which may be summarised as follows.

Stage 1: Load: Add water, dispersants, some defoamer as required to control against foam and alkali soluble ink polymer and under agitation using a cavitation mixer such as a TORRACE mixer, add enough substituted amine, such as MEA or TEA, to neutralize this mixture to desired pH, add the coalescent if used. A suitable defoamer is manufactured by Henkel under the trade mark Foamaster NS-I .

Stage 2: At this point the pigment (and extender if used) is added, either in powder form, or possibly as a pre-dispersed liquid which has already been processed in a bead mill

Stage 3 : Add a portion of the thickener and disperse.

Stage 4: Let down: Add the acrylic binder dispersion, the rheology modifiers and remainder of the thickener and the propylene glycol.

Paint Ingredients Differ per Manufacturer

Things get complicated when you want to know the exact ingredients that are in the binder. Each manufacturer has their formula, and some include ingredients designed to cut costs.

Paints may also include any variety of additives. Surfactants, for example, are used to disperse pigments, and anti-foaming agents stop the paint from frothing as you use it. Cheaper paints may contain things that cost less than actual pigments, such as fillers, opacifiers, or dyes.

Different brands of paint also contain different proportions of pigment. This is known as pigment loading. If you’ve tried various brands of what is supposed to be the same color, you may have encountered this. It can often be very apparent that the colors of one brand are more intense than others.

For all of these reasons, artists often stick with one paint manufacturer. Then again, some artists find that a particular manufacturer produces a specific color that they like more than others. Artists tend to be very loyal when they see find they enjoy.

Whether You Can Make Your Acrylic Paint

Many oil painters like to mix their paints, but is this possible with acrylics? You can make acrylics as well. However, given the nature of acrylic paint, it is trickier. You’ll have to work fast.

Speed is crucial because of the primary difference between oil and acrylic paints: acrylics are water-based, so they dry faster. The same speed you use when painting is the speed you need to use when mixing.

How to Mix Acrylic Paint

Other than speed, mixing acrylics is relatively easy, though it is not as simple as oils. At it’s most basic, an acrylic paint recipe requires a pigment and a binder, and you will need a container to store the paint. There are other additives that you can add as well.

For the pigment, you have two choices:

You can use dry pigment. The same as is used for oil paints. That’s because it’s a universal ingredient common in both types of paint.

You will need to grind the pigment into a base of either water or alcohol. Organic pigments will disperse much better in alcohol, and you will add water before that evaporates. Kama Pigments’ tutorial for how this is done is excellent because it offers solutions to problems you might encounter.

The other pigment option is called an aqua-dispersion, such as that sold by Kama Pigments. These have already taken care of the most difficult part of mixing acrylics because the pigment has been dispersed into a water base for you. All you have to do is mix it with the binder.

When it comes to the binder, you can use almost any acrylic medium that you would normally mix with a standard tube of acrylic paint. As explained on PaintMaking.com, a “binder medium” is the basic medium for this purpose, but you can also choose a gel medium, impasto medium, or iridescent medium. Each of these options will produce different effects in your finished paint.

While mixing your acrylics does come with some hassle and a learning curve, the flexibility it offers you to create custom paints can make it worthwhile in the long run.

Profile

Art Materials Expert at PIGMENT TOKYO

Born in 1989 in Tokyo. Master of Fine Art and Design at Nihon University College of Art. While working at PIGMENT TOKYO as an Art Materials Expert, he also continues his career as a visual artist.

Born in 1989 in Tokyo. Master of Fine Art and Design at Nihon University College of Art. While working at PIGMENT TOKYO as an Art Materials Expert, he also continues his career as a visual artist.

- Treasure Box of Color “ Oil Pastel”

- Drawing On The Silk -Aesthetics Of Translucent –