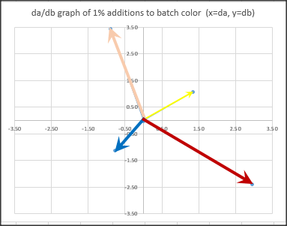

Let’s start with a batch of paint having a beige color and the following Lab values:

L=67, a=3 and b=9

Converting SW Paint Formula to RGB?

I have some custom mixed Sherwin Williams paints that I whose colours’ I want to duplicate in CAD software. I sent an email to SW Customer Service asking them for the RGB colour formula equivalents to their formulas but got no reply.

I’ve searched the web and haven’t found anything.

Other than painting a sample and duplicating on my computer through hit and miss (could take forever!), I don’t have any idea how to do this.

Replies

BarryE | Oct 03, 2006 04:50am | #1

Barry E-Remodeler

e2canoe | Oct 03, 2006 08:49pm | #2

Thanks. I found that website and it sure is neat but it doesn’t help me with custom mixed paints – only the standard colours. I think I’ll just find the closest match in a fan deck and will then use that site.

PaulBinCT | Oct 03, 2006 09:00pm | #3

See if your friendly local photolab has a densitometer that reads RGB in reflection mode. Won’t be precise but oughta be pretty close. (BTW. are you sure you don’t want CMYK?) PaulB

e2canoe | Oct 03, 2006 11:04pm | #6

RGB, CMYK or HSV. Doesn’t matter.

pino | Oct 04, 2006 12:53am | #8

Not to be picky, but what you want is a spectrocolorimeter or colorimeter. A densitomiter just measures density, thus grayscale. At least I think so.You can pick one up with software for around $500.00

PaulBinCT | Oct 04, 2006 03:29am | #10

Nyet. Trust me, 25 years in the photolab industry 😉

pino | Oct 04, 2006 03:42am | #11

Ever hear of Burrell Color? They used to be a good client of mine.

PaulBinCT | Oct 04, 2006 02:37pm | #14

Sure, know them well. they were IIRC a “social” lab, mainly weddings, portraits, yearbooks. We were exactly the opposite, did mainly high end commercial, ad agencies, medical, that sort of thing. Small world. PaulB Edited 10/4/2006 7:39 am ET by PaulBinCT

JohnSprung | Oct 04, 2006 09:32pm | #15

A friend of mine also did some medical video work. That’s a place where color is exceptionally critical because they’re deciding what’s wrong with you, or what to cut off of you, depending on the color. Making TV shows, we sometimes call things “broadcast quality”. The doctors he worked with had a term of their own for not quite good enough: “malpractice quality” video. 😉 — J.S.

PaulBinCT | Oct 05, 2006 02:52pm | #16

LOL. We did essentially all the lab work for Yale’s Med School. There were only certain staff people (not including me) that could handle looking at that stuff under a high power loupe.

JohnSprung | Oct 03, 2006 10:11pm | #4

Actually, it’s worse than that. There’s no one natural choice of what the Red, Green, and Blue primaries should be. Each video standard picks its own — like SMPTE-C, CCIR Rec 601, CCIR Rec 709. And there’s no requirement that computer monitors or TV sets be made with phosphors that cover the gamuts specified in the standards. They have knobs that the end user can turn to make the colors look the way they want, so calibrating them is another mess. Here are a couple good sources of basic info: http://www.poynton.com/ColorFAQ.html http://en.wikipedia.org/wiki/CIE_1931_color_space

e2canoe | Oct 03, 2006 11:05pm | #7

Ya. I know that monitors will vary (witness the “colour temperature” setting that modern monitors come with). But, want to get close at least.

JohnSprung | Oct 04, 2006 01:42am | #9

OK, for getting close, what you need to do first is get your monitor set up in some reasonable way. Here’s how we do it in the TV business: http://www.videouniversity.com/tvbars2.htm You need a computer equivalent. Google around and see if anything helps. This is one that I found that way: http://www.pawprint.net/designresources/monitorcalibration.php When you’re satisfied that your monitor is pretty close to telling you the truth, take your paint samples, go into PhotoShop or whatever you have that lets you put in RGB numbers, and go for it with trial and error. The brightness and color temperature of the light you use to see the paint chips is also critical. For “close”, just be sure to use the same lamp and bulb at the same distance every time. And make sure there’s no other source of contaminating light. Halogen would be the best choice for color, and any kind of flourescent the worst. Then do the setup thing again on a different machine, compare the chips, and you now know the meaning of “close”. 😉 — J.S.

e2canoe | Oct 04, 2006 04:44am | #12

Thanks you very much. That’s very helpful. I’ll also try printing (ink jet) my rendered building with the paint colours (I found close Pratt & Lambert colours that I converted using easyrgb.com) and see how close it ends up to the fan deck cards.

Piffin | Oct 04, 2006 06:00am | #13

P&L is owned by SW now. They have both colour formulaas Welcome to the Taunton University of Knowledge FHB Campus at Breaktime. where . Excellence is its own reward!

Piffin | Oct 03, 2006 10:39pm | #5

Interesting concept, but there will be variations of display and/or printing between different monitors and printers anyway, gauranteeing an inconsistant outcome

Welcome to the

Taunton University of Knowledge FHB Campus at Breaktime.

where .

Excellence is its own reward!

Formula converter for paint colors

Malaysia’s No.1 Paint Brand

- Interior Wall

- Spot-Less Plus

- Vinilex Fresh Plus

- Easycoat

- EA4 Finish Non-Skid

- VirusGuard

- Odour~Less AirCare

- Perfect White

- Odour~Less Premium All-in-1

- 3-In-1

- Satin Glo

- EasyWash

- Q-Matt Classic

- Q-Glo

- Matex Gold

- Super Matex Colour Creations

- Super Matex

- Exterior Wall

- Royal Stone

- Classic Tiles

- EA4 Finish Texture

- Weatherbond Advance

- Weatherbond Hi-Gloss

- Weatherbond Solarflect Extreme

- Q-Shield Extra

- Matex WeatherGold

- Wood & Metal (Solid Colour)

- Odourlite Soft Matt Finish

- Odourlite Gloss Finish

- Hydro Finish

- 9000 Gloss Finish

- Q-Lac Gloss Finish

- Platone High Gloss

- Timbershade

- Metallic Paint

- Wood (Pigmented Varnish)

- Hydro Wood

- 1 Pack PU Timbercoat

- Timber Finish

- Fibercote

- Roof

- Solaroof

- Roof Coating

- Floor & Road

- Roadline Paint (Non-Reflective)

- Aqua Epoxy

- Multi-Purpose Floor Coating

- Roadline Paint (Reflective)

- Tile

- Momento® Textured Series – Elegent

- Aqua Epoxy

- Bare Cement

- Water Repellent Solution

- Slate & Pebble Wash

- Slate Finish – Gloss

- Interior Wall

- 8000 Advance Sealer

- 5200 Interior Sealer

- 5500 Wall Sealer

- 5400 Wall Sealer

- Acrylic 5170 Wall Sealer

- Hi-Bond Wall Sealer

- Exterior Wall

- 8000 Advance Sealer

- 5100 Wall Sealer

- 5500 Wall Sealer

- Acrylic 5170 Wall Sealer

- Flexiseal Elastomeric Membrane

- Floor

- Aqua Epoxy Primer

- Acrylic 5170 Wall Sealer

- Penetrative Epoxy Primer

- Tile

- Roof

- Roof Primer

- Acrylic 5170 Wall Sealer

- Undercoat

- 9000 Aluminium Wood Primer

- Aquatec Red Oxide Primer

- Odourlite Undercoat

- 9000 Undercoat

- Economy Undercoat

- EA9 Red Oxide Primer

- Pylox Lazer

- Stone Art Clear Coat

- Momento Clear Coat

- Fungicidal Wash

- Multi-Purpose Joint Compound

- Interior Wall

- VirusGuard

- Odour~Less AirCare

- Wood & Metal

- Hydro Finish

- Hydro Wood

- Interior Wall

- 5200 Interior Sealer

- Wood & Metal

- Momento® Primer

- Momento® Textured Series – Elegent

- Momento® Textured Series – Sparkle Silver

- Momento® Textured Series – Sparkle Pearl

- Momento® Textured Series – Sparkle Gold

- Momento® Textured Series – Elegant Gold

- Floorshield Self Levelling Epoxy Finish

- Momento® Enhancer Series – Cloud Pearl

- Momento® Enhancer Series – Cloud Gold

- Momento® Enhancer Series – Snow Frost

- Momento® Enhancer Series – Pearl Frost

- Momento® Enhancer Series – Gold Frost

- Momento® Designer Series – Velvet Pearl

- Momento® Designer Series – Velvet Gold

- Momento® Designer Series – Velvet Metallic

- Momento® Designer Series – Optical

- Momento® Designer Series – Rust Box

- Momento® Travertino Series

- Metallic Paint

- Micaceous Iron Oxide

- Tilelac Ema Base

- Stone Art

- Stone Art Clear Coat

- Momento Clear Coat

- PU Recoatable Finish

- PU Recoatable Finish Clear

- Acrylic Finish Topcoat

- EA4 Finish (EP)

- EA9 Finish HB

- Protective Finish FD

- Metallic Paint

- Micaceous Iron Oxide

- Zinc Phosphate Primer

- Galvaprimer

- Etching Primer 120

- Penetrative Epoxy Primer

- 7” Solvent-Based Roller Refill

- 7” Exterior Roller Refill

- 4” Water-Based Roller Refill

- 4” Solvent-Based Roller Refill

- 7” Interior Roller Refill

- 7” Polyester Roller Refill

- 4” Polyester Roller Refill

- Heavy Duty Aluminium Extension Pole 100-2M

- Heavy Duty Aluminium Extension Pole 100-4M

- 7” End Cap Heavy-Duty Roller Handle

- 4” Single Wire Heavy-Duty Roller Handle

- Momento Toolkit

- 1” Synthetic Filament Paint Brush

- 1.5” Synthetic Filament Paint Brush

- 2” Synthetic Filament Paint Brush

- 2.5” Synthetic Filament Paint Brush

- 3” Synthetic Filament Paint Brush

Live Chat

Roadshows

Locate Us

Colour

Card

Interior Wall

- Interior Wall

- Spot-Less Plus

- Vinilex Fresh Plus

- Easycoat

- EA4 Finish Non-Skid

- VirusGuard

- Odour~Less AirCare

- Perfect White

- Odour~Less Premium All-in-1

- 3-In-1

- Satin Glo

- EasyWash

- Q-Matt Classic

- Q-Glo

- Matex Gold

- Super Matex Colour Creations

- Super Matex

- Exterior Wall

- Royal Stone

- Classic Tiles

- EA4 Finish Texture

- Weatherbond Advance

- Weatherbond Hi-Gloss

- Weatherbond Solarflect Extreme

- Q-Shield Extra

- Matex WeatherGold

- Wood & Metal (Solid Colour)

- Odourlite Soft Matt Finish

- Odourlite Gloss Finish

- Hydro Finish

- 9000 Gloss Finish

- Q-Lac Gloss Finish

- Platone High Gloss

- Timbershade

- Metallic Paint

- Wood (Pigmented Varnish)

- Hydro Wood

- 1 Pack PU Timbercoat

- Timber Finish

- Fibercote

- Roof

- Solaroof

- Roof Coating

- Floor & Road

- Roadline Paint (Non-Reflective)

- Aqua Epoxy

- Multi-Purpose Floor Coating

- Roadline Paint (Reflective)

- Tile

- Momento® Textured Series – Elegent

- Aqua Epoxy

- Bare Cement

- Water Repellent Solution

- Slate & Pebble Wash

- Slate Finish – Gloss

- Interior Wall

- 8000 Advance Sealer

- 5200 Interior Sealer

- 5500 Wall Sealer

- 5400 Wall Sealer

- Acrylic 5170 Wall Sealer

- Hi-Bond Wall Sealer

- Exterior Wall

- 8000 Advance Sealer

- 5100 Wall Sealer

- 5500 Wall Sealer

- Acrylic 5170 Wall Sealer

- Flexiseal Elastomeric Membrane

- Floor

- Aqua Epoxy Primer

- Acrylic 5170 Wall Sealer

- Penetrative Epoxy Primer

- Tile

- Roof

- Roof Primer

- Acrylic 5170 Wall Sealer

- Undercoat

- 9000 Aluminium Wood Primer

- Aquatec Red Oxide Primer

- Odourlite Undercoat

- 9000 Undercoat

- Economy Undercoat

- EA9 Red Oxide Primer

- Pylox Lazer

- Stone Art Clear Coat

- Momento Clear Coat

- Fungicidal Wash

- Multi-Purpose Joint Compound

- Interior Wall

- VirusGuard

- Odour~Less AirCare

- Wood & Metal

- Hydro Finish

- Hydro Wood

- Interior Wall

- 5200 Interior Sealer

- Wood & Metal

- Momento® Primer

- Momento® Textured Series – Elegent

- Momento® Textured Series – Sparkle Silver

- Momento® Textured Series – Sparkle Pearl

- Momento® Textured Series – Sparkle Gold

- Momento® Textured Series – Elegant Gold

- Floorshield Self Levelling Epoxy Finish

- Momento® Enhancer Series – Cloud Pearl

- Momento® Enhancer Series – Cloud Gold

- Momento® Enhancer Series – Snow Frost

- Momento® Enhancer Series – Pearl Frost

- Momento® Enhancer Series – Gold Frost

- Momento® Designer Series – Velvet Pearl

- Momento® Designer Series – Velvet Gold

- Momento® Designer Series – Velvet Metallic

- Momento® Designer Series – Optical

- Momento® Designer Series – Rust Box

- Momento® Travertino Series

- Metallic Paint

- Micaceous Iron Oxide

- Tilelac Ema Base

- Stone Art

- Stone Art Clear Coat

- Momento Clear Coat

- PU Recoatable Finish

- PU Recoatable Finish Clear

- Acrylic Finish Topcoat

- EA4 Finish (EP)

- EA9 Finish HB

- Protective Finish FD

- Metallic Paint

- Micaceous Iron Oxide

- Zinc Phosphate Primer

- Galvaprimer

- Etching Primer 120

- Penetrative Epoxy Primer

- 7” Solvent-Based Roller Refill

- 7” Exterior Roller Refill

- 4” Water-Based Roller Refill

- 4” Solvent-Based Roller Refill

- 7” Interior Roller Refill

- 7” Polyester Roller Refill

- 4” Polyester Roller Refill

- Heavy Duty Aluminium Extension Pole 100-2M

- Heavy Duty Aluminium Extension Pole 100-4M

- 7” End Cap Heavy-Duty Roller Handle

- 4” Single Wire Heavy-Duty Roller Handle

- Momento Toolkit

- 1” Synthetic Filament Paint Brush

- 1.5” Synthetic Filament Paint Brush

- 2” Synthetic Filament Paint Brush

- 2.5” Synthetic Filament Paint Brush

- 3” Synthetic Filament Paint Brush

Get started with our paint assistant

Paint Calculator

Find out the ideal paint amount for your walls.

Walls/Surfaces to paint

- Surface

- Width

- Height

- 1

- x

Ceiling (optional)

* Surface area similar to floor measurements

Areas to exclude (windows, doors, vents, etc.)

- Section

- Width

- Height

PLEASE NOTE

Calculations assume 2-coats of paint & are estimated figures only. Precise paint needs will vary according to many factors, including application method.

For more accurate calculations, please refer to our TSDS or contact us for more information.

Recommended amount of paint

(half of recommended paint amount)

(half of recommended paint amount)

PAINT ESTIMATOR

Type Of Dwelling

Location

No. of 5 Litre Cans Required

Location

No. of 5 Litre Cans Required

Each Bedroom (Walls)

Each Living Room

All Ceilings

All Wood & Metal

External Walls

Type Of Dwelling

Location

No. of 5 Litre Cans Required

Each Bedroom (Walls)

Each Living Room

All Ceilings

All Wood & Metal

External Walls

Type Of Dwelling

Location

No. of 5 Litre Cans Required

Each Bedroom (Walls)

Each Living Room

All Ceilings

All Wood & Metal

External Walls

- About Us

- News & Events

- Media Room

- Careers

- Corporate & Community Outreach

- Contact Us

- Terms & Conditions

- Personal Data Protection Act (PDPA)

NIPPON PAINT (M) SDN. BHD. (196701000578)

Lot I-17, Taman Perindustrian Subang Utama, Jalan SU4, 40300 Shah Alam, Malaysia.

NIPPON PAINT (M) SDN. BHD. (196701000578)

Lot I-17, Taman Perindustrian Subang Utama,

Jalan SU4, 40300 Shah Alam, Malaysia.

Customer Careline: 1-800-88-2663 | Email: [email protected]

Customer Careline:

1-800-88-2663

Email:

[email protected]

Note: The colour shades displayed are indicative and not precise representations of our actual paint colours.

© 2023 NIPPON PAINT (M) SDN. BHD. (196701000578) All Rights Reserved

In Memory of

Mr. Kenji Sakai

EX-Chairman of the Board at Nippon Paint Holdings Co Ltd.

0000 – 2018

The Management and Staff of Nippon Paint Malaysia Group

are saddened to share the news that our Ex-Chairman of the

Board at Nippon Paint Holdings Co Ltd., Mr Kenji Sakai has

passed away on May 1, 2018.

We would like to take this day to mourn the loss of a

respected leader and a dear friend of ours as well as honour

his service and dedication in setting a great legacy here at

Nippon Paint.

Our deepest condolences to the family of Mr. Kenji Sakai.

May you rest in peace.

The Initial Batch Differences under Three Light Sources

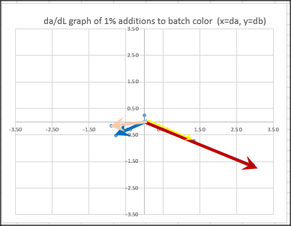

Now, lets look at the da/db and da/dL graphs of standard color compared to batch color:

The differences under three light sources are connected with each other through straight lines. Ideally, all points would be at the origin, meaning that the color differences are zero. Looking at the da/db diagram, adding Blue would reduce the difference between standard color and batch color. However, this would not help the color in the da/dL graph. We also see that the Yellow and Red colorants have an opposite effect in the da/db diagram, but not so in the da/dL diagram. So, finding the optimal additions and making sure that the number of colorants is minimized is not so easy to see, especially if more than one light source needs to be considered, as well as other aspects like minimizing the metameric effect between light sources.

The Excel Solver in Action

Now how can we use Excel to calculate the best additions and taking this intricate play of color influences into account?

Let’s start by using the Solver in Excel. We need the 1% tinting table and the dL, da, and db differences under three light sources of the batch compared with the standard. Because the correction additions of this second table are zero when we start, their influences are also zero. And, therefore, the differences before and after the optimization are the same.

With the Data/Solver function of Excel, the following screen pops up. In the ‘Set Objective’ field, the cell that needs to be minimized is indicated, and in the field ‘By Changing Variable Cells’ the concentration of the colorants to add are indicated by Correction. We check the box labelled ’Make Unconstrained Variables Non-Negative’ to make sure colorants can only be added. (Note that all cells refer to each other with underlying function, like dE = =(J23^2+J24^2+J25^2)^0.5), etc.)

Then we press the Solve button…

The combined dE value decreased from 1.25 to 0.46, a substantial reduction.

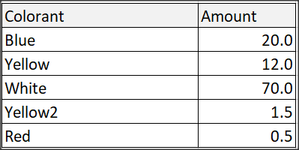

The Solver Results Analyzed

Looking at the shift in de da/db and da/dL diagram the Solver was successful i.e the green lines are much closer to the origin that the initial red lines.

Also, the combined color difference under three light sources is reduced from 1.25 to 0.46 by adding 1.2 Blue, no Yellow1, 6.2 White, 0,5 Yellow2, and 0.39 Red. Well, this seems a rather big beneficial step. However, the additions are substantial, i.e. 8.3. Can we achieve similar success with less addition? Yes, we can!

Let’s first look at the colorants. Perhaps they are working against each other. From Graph 1, it can be concluded that some colorants partly work against each other. There is, however, an alternative way to detect this. Using the Data/Data Analysis/Correlation option on the tinter table, we obtain the following table:

It is easy to see that Blue and Yellow 2 are negatively correlated, which means that if one of them are set to zero, the other will be less also. We run the Solver again and set the value of Yellow 2 as constraint to 0. Hitting Solve produces the following table:

And indeed, the additions go from 8.3 to a total of 2.2 and the combined dE hardly increased. Using these options, you can play around with different constraints to see what happens with the color of your batch.

One of the aspects that is important for some businesses is the metameric index (MI) and the combination of MI with color difference. For instance, a specification on dE might require it to be smaller than 0.5 AND the metameric index to be smaller than 0.5 as well. In our example, this effect would however be rather minimal.

Closing remarks

-

-

- As remarked earlier, dedicated software programs are more sophisticated and take more aspects of batch control into consideration than this example Excel sheet. These programs make sure the vessel will not overflow, and can add the correction colorants not present in the mixture. However, they are sometimes not flexible enough regarding the parameters that need to be optimized. Excel enables us to involve various criteria in the optimization not supported by regular software, such as the combination of color differences and metameric indexes. Also, weighing factors could easily be introduced in Excel on different levels.

- Consider Excel as an intelligent calculator to support your problem in cases where a regular software doesn’t give the right answers.

- Dedicated software programs do not calculate with a 1% tinting table. They work with the derivative of the optical model which is better and can cause substantial differences. This especially happens in case of colorants with a very high influence on the color of the batch i.e. a high color sensitivity. However, if there is no sound optical model available, the 1% tinter table method still works!

Roel Gottenbos is an experienced color research manager and developer of game changing color tools. He helps companies to improve their color processes from raw material to end product. Roel has the privilege to work together with Erik van Biemen within Color Technology Consultancy.

Please contact us if you need more information or would like to comment on the content of this publication: [email protected].

-